In March of 2019 I saw a brochure from Southern Maine Community College. They were offering a course in Precision Machining. I asked my son Mike if he wanted to take the course. He said we both should take the course, it would be fun to do something with me. Why would a 76 year old want to take a college course?

Hey, it’s with my son who’s a metal genius. And it indeed was fun.

We both learned how to work with huge lathes, milling machines and precision grinders.

The thing you see above was one of the first things I made. Notice that it has both outside and in inside threads, both done on a huge lathe.

After the course I bought my big lathe (7” x 12”) above. I did have a small lathe, but it couldn’t do some of the things I wanted to make. Beautiful, eh?

After I got my lathe I made a lot of artsy things.

Here are come other things.

A couple rings I made Mr. Bug

This is actually a steel ring made with an acrylic ring blank that goes over the ring and is turned down. This wasn’t my best. Gave the good ones away.

This is supposed to be a spider, but it’s not your common spider, it looks more like an ant spider. It does have eight legs. I think I actually modeled it from a real spider that lives somewhere else on earth.

The image on the left is a Chorten, which is a Tibetan Buddhist shrine or monument. The image on the right is the Chorten on the lathe. It started out as 8 lbs of brass, and is now 3.5 lbs.

This is a flute stand that I made from Acetal Copolymer for my sister-in-law who plays four different size flutes.

This is a flute stand that I made from Acetal Copolymer for my sister-in-law who plays four different size flutes.

The tire on my wheel barrow went flat and I couldn’t get another. So I ordered a solid wheel. To make it fit on the wheel barrow I had to make a new axel for it; the shiny thing between the two dark tubes. The old axel is below it.

So, on the left is a candle stick, and on the right is a candle.

We picked this candy dish up at a yard sale, but it only had a smooth glass handle that was pretty slippery. Now it’s not.

On the left is a Finial. A finial is the top of a lamp that holds the shade on. It has a special screw thread, not a standard thread. On the right is an incense holder. I can make these things for you.

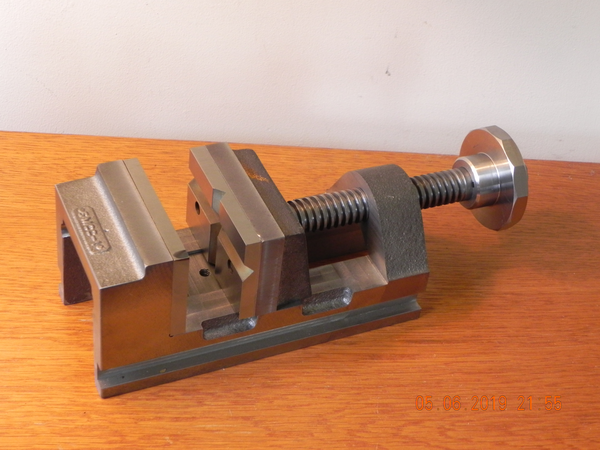

My son gave me this vise for my birthday. He took the 2nd Precision Machining course the next year at the Southern Maine Community College. He made this on the Lathe, the Milling Machine, and the Precision Grinding Machine. He also learned how to run the CNC (Computer Numerical Control) machines. That’s his job now, making precision mill ends for the government, industry, and airplane manufacturers.

When I got my first lathe while living in New York in 1966, a “Unimat DB200 Mini Lathe 3”, above, it was very small, but a wonderful machine.

I was able to make a lot of things on it, however. I had a friend who wanted me to make a little hash pipe for him. I did, and that gave me the idea to make a pot pipe. But it had to be in disguise. It worked out very well and I sold it for $20, $193 in today’s money.

When I was at the machining course I decided to make one and call it a puzzle so the instructor wouldn’t object to it, we had to name our projects. It turned out really well, and he finally figured out what I made, but he didn’t really object to it because I did it so sell.

When I got my big lathe I made some more, only better looking. Here’s the ancient puzzle:

I can make one for you.